3 CASOS D’ÈXIT DEL FARCIMENT PLÀSTIC BIOFILL® TIPUS A, 26 ANYS EN SERVEI SENSE SER SUBSTITUÏT

L’EDAR MUNICIPAL DE LA POBLACIÓ DE BALSARENY, L’EDAR D’UNA INDUSTRIA TÈXTIL I L’EDAR D’UNA EMPRESA FARMACÈUTICA MULTINACIONAL, LES TRES PROPERES A BARCELONA, SEGUEIXEN FUNCIONANT A PLE RENDIMENT, 26 ANYS DESPRÉS DE LA SEVA INAUGURACIÓ, AMB EL MATEIX FARCIMENT PLÀSTIC BIOFILL® TIPUS A QUE ES VA INSTAL·LAR EL PRIMER DIA

CAS Nº 1.- BALSARENY ( 1989)

La planta depuradora de la ciutat de Balsareny (Barcelona, Espanya) va ser la primera planta depuradora inaugurada a Espanya mitjançant el sistema de filtre percolador amb un farciment plàstic en lloc de farciment mineral com es feia fins aquell moment.

La planta depuradora d’aquesta ciutat segueix funcionant sense cap tipus de problemes després de 26 anys d’haver estat inaugurada, el 1989, i sense necessitat d’haver introduït canvis en el seu disseny ni sistema de funcionament.

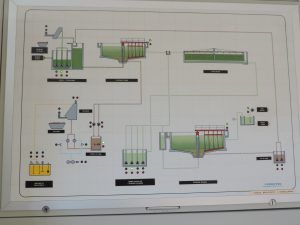

La instal·lació consta d’un desbast de sòlids gruixuts, un desbast de sòlids fins, un decantador primari, un filtre percolador amb “farciment plàstic BIOFILL® tipus A” i decantació secundària.

Espanya és un país muntanyós amb nombrosos rius de poc recorregut, amb poc cabdal excepte en èpoques de pluges, que acullen una gran riquesa de fauna i flora. En les dècades dels anys 60 i 70, el país havia experimentat un alt creixement industrial, sobretot a l’àrea geogràfica de Catalunya (nord-est d’Espanya) i totes les regions nord del país. Les indústries tèxtils, metal·lúrgiques i papereres van anar contaminant gradualment els rius fins a convertir-los en clavegueres a cel obert que pràcticament van fer desaparèixer la vida d’aquests rius.

| Fins aquell moment, molt poques plantes depuradores d’aigües residuals s’havien construït a Espanya i la major part es limitaven a un tractament físic-químic, excepte en alguna gran ciutat. En alguns casos era mitjançant filtre percolador amb farciment mineral. El sistema físic-químic suposava un alt cost en reactius, una alta producció de fangs i un escàs rendiment en l’eliminació de la càrrega orgànica dissolta (70 % aproximadament) en el millor dels casos. Les plantes biològiques de filtre percolador amb farciment mineral tampoc donaven un gran rendiment i a més s’obstruïen amb facilitat. |

Filtre percolador amb farciment mineral |

El Govern autonòmic de Catalunya, assessorat per tècnics de la universitat, va proposar a una empresa d’enginyeria el disseny d’una planta depuradora d’aigües residuals que funcionés amb filtre percolador amb baix cost energètic i d’alta eficiència en el seu funcionament, per instal·lar-la en una població amb un gran component industrial i al costat del riu que havia perdut la vida que havia tingut. Aquesta planta es va instal·lar a la població de Balsareny al costat del riu Llobregat.

El procés de depuració és el que es mostra en el diagrama anterior i físicament és com es mostra a continuació.

Vista general de la planta

La planta es va construir durant els anys 1988 i meitat de 1989, instal·lant-se com a element de farciment del filtre percolador el producte anomenat BIOFILL® tipus A, aquest s’havia començat a fabricar justament l’any 1988 per l’empresa CEPICMA, la qual havia desenvolupat el producte a partir d’un disseny italià, modificat posteriorment gràcies a diversos estudis pilot en col·laboració amb la Universitat. L’èxit va ser tan rotund que es van instal·lar diverses plantes depuradores en poblacions de la mateixa conca hidrogràfica durant els anys següents.

|

Com es pot apreciar, l’adherència de la biomassa al farciment és total i no disminueix el volum lliure que permet el pas de l’aigua. |

CAS Nº2.- INDUSTRIA TÈXTIL (1993)

La industria tèxtil presenta en general graus de contaminació dispars ja que depèn del subsector al qual pertany (tints, acabats, estampació, etc), però quasi totes tenen una característica en comú: el color.

Les primeres industries tèxtils que van instal·lar la seva planta depuradora tractaven les aigües residuals mitjançant sistemes físic-químics de coagulació-fluculació, amb un fort consum de reactius químics, produint una gran quantitat de fangs. Aquestes plantes, si estaven correctament dissenyades i la seva explotació era correcta (cosa que no passava sempre), aconseguien eliminar el color, però a les aigües quedava una càrrega contaminant orgànica molt important que en general superava els límits legals d’abocament a riu.

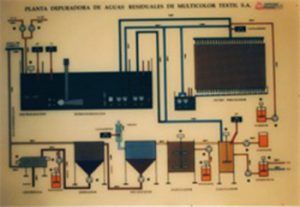

Es va realitzar un estudi a escala real patrocinat per l’ICAEN, realitzat entre la Universitat Politècnica de Catalunya i una empresa tèxtil situada al curs alt del propi riu Llobregat, on la conservació de la fauna piscícola era una acció estratègica per la regió situada al peu de la serralada dels Pirineus. L’estudi va consistir en assajar la combinació d’un sistema biològic de filtre percolador amb el farciment plàstic BIOFILL® tipus A i el sistema físic-químic existent.

Diagrama de fluxe |

Vista filtre percolador |

El projecte va consistir en introduir un sistema biològic de filtre percolador equipat amb BIOFILL® tipus A; entre el dipòsit d’homogeneïtzació i el sistema físic-químic existent, l’aigua percolada es va enviar al dipòsit d’homogeneïtzació activant-lo amb aire suficient, des del qual s’enviava l’aigua al sistema físic-químic. Aquesta combinació va comportar una disminució dràstica del consum de reactius i, com a conseqüència, la disminució de la producció de fangs al voltant del 50% en volum.

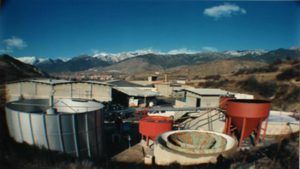

Vista general de la planta modificada

| La biomassa que es forma en el tractaments de las aigües residuals industrials és completament diferent de la que es forma en aigües residuals domèstiques, en primer lloc perquè els components a degradar són diferents i en segon lloc perquè adquireix el color de l’aigua que es tracta a la planta, i en el cas de la industria tèxtil el color pot ser divers.

La construcció del filtre percolador no ha de ser necessàriament de formigó: el dipòsit està ple de plàstic, no d’aigua, per la qual cosa no hi ha impuls lateral sobre les seves parets, que poden ser tan simples com les que es veuen en aquest exemple. En aquest cas la construcció es va realitzar en acer inoxidable 304, però pot ser d’acer galvanitzat o d’acer vitrificat, sempre en funció del pressupost que s’hi vulgui o pugui dedicar. L’èxit de l’experiència va permetre no només eliminar el color, sinó més del 93% de la càrrega orgànica dissolta. Aquest èxit va portar a construir moltes més plantes amb aquest sistema en el sector tèxtil. |

Biofill A amb residuu |

CAS Nº3.- INDUSTRIA FARMACÉUTICA (1989)

Una industria multinacional farmacèutica amb dos centres de producció en Catalunya (àrea de Barcelona) disposava de plantes depuradores de prestacions reduïdes. La nova legislació mediambiental del Govern autonòmic va obligar a la construcció d’una nova planta que permetés complir amb el reglament corresponent. Tot i que els seus abocaments s’efectuen a un sistema d’abocament municipal, les altes càrregues de les seves aigües residuals van obligar a un disseny amb diverses etapes per assolir els valors desitjats.

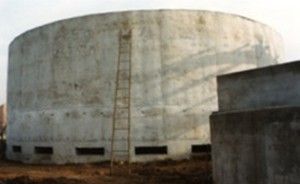

La propietat va encarregar el disseny i construcció de la planta d’una de les seves fàbriques a una prestigiosa enginyeria barcelonesa. El disseny incloïa la instal·lació d’un dipòsit d’homogeneïtzació, una decantació primària, dos sistemes biològics en sèrie el primer es un filtre percolador d’alta carrega que es va equipar amb farciment plàstic BIOFILL® tipus A i segon va ser un sistema de fangs actius, finalment un sistema físic-químic, a més de la decantació secundaria i la deshidratació de fangs.

El primer dels sistemes biològics és un filtre percolador d’alta càrrega construït l’any 1989, que elimina una gran part de la contaminació dissolta. El sistema funciona des del seu inici amb el mateix farciment BIOFILL® tipus A sense necessitat d’haver-lo hagut de substituir ni afegir més farciment.

Vista exterior del filtre percolador |

Vista interior del filtre en funcionament |

L’èxit del funcionament va ser tan rotund que dos anys més tard la propietat va encarregar a la mateixa enginyeria una planta idèntica per a la seva altra fàbrica a Catalunya

Així doncs tindríem no tres sinó quatre casos d’èxit del farciment BIOFILL® tipus A, tres d’ells des de fa 26 anys i un quart des de fa 24.

CONCLUSIONS

El resultat va ser espectacular, instal·lant el filtre percolador anterior al físico-químic en tots els casos, activant la homogeneïtzació i des d’aquí alimenant el físico-químic. Així es va aconseguir:

- Eliminar la càrrega orgànica dissolta fins a límits que van permetre abocar l’aigua depurada al riu, complint la legislació per a zones sensiblement protegides.

- Reduir dràsticament el consum de reactius.

- Reduir la producció de fangs a menys de la meitat.

- Reduir els costos d’explotació a menys de la meitat.

El BIOFILL® tipus A instal·lat per la realització dels projectes no s’ha hagut de substituir en cap dels casos. Posteriorment, aquest sistema s’ha utilitzat freqüentment, no només en la industria tèxtil, sinó també en altres sectors industrials.